We’ll discuss key factors to consider when selecting a rotary tiller, such as the size of your tractor, the width and depth of the tiller, and the number of tines it has. We’ll also explore the benefits of a PTO-driven tiller and the importance of having a strong and durable gearbox. By the end of this post, you’ll have all the information you need to choose the best rotary tiller for your tractor and make sure your land is ready for planting season.

Table of Contents

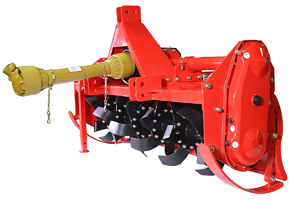

1. King Kutter – Best Rotary Tiller for a Tractor

King Digger

While the name may evoke a time when King Kutter primarily focused on grass and cutting implements, they possess an innate ability to assess a product and determine its potential for extensive use. King Kutter may not always offer every convenient feature that may not directly affect performance, but they consistently deliver some of the most powerful implements in the market. In this case, the TG-84 stands out as the most powerful tiller available, although it requires higher power requirements compared to its competitors.

Technical Aspects

The remarkable power of King Kutter tillers can be attributed to their employment of a cast iron gearbox and a heavy-duty gear drive. It is worth noting that the TG-84 is also the largest tiller on our list, measuring 72″ in width, which often allows for a single pass without compacting the previously tilled soil. Additionally, the King Kutter tiller boasts the highest number of digging tools, featuring 54 tines distributed across 9 flanges, all of which are exceptionally durable. This robustness is further reinforced by a gear-driven shaft and the thickest body among the models we examined, although it does result in being the heaviest as well.

- Is a 72” tiller

- Has 54 total tines

- Has 9 total flanges

- Has the most cutting power

- Has cast iron gearbox

- The most durable tiller reviewed

- The most expensive tiller reviewed

- Has the highest power requirements

2. Titan Attachments – Best All-Around Value Rotary Tiller for a Tractor

Reasonably Powerful

While the Editor’s Choice may top the charts in every category, the Titan Attachment makes a respectable showing in a number of features. For instance, this tiller still provides a solid 60” working width which is not only second on our list but also the point where the tiller may cover the width of the tractor. The Titan Attachments has a solid 36 tines on 6 total flanges with a cutting swing of 18” which will help reduce the number of bucks and jams from hitting rocks. In fact, the tines themselves are fairly impressive coming in at a hefty 28 oz and ¼” thick while still being easily replaced if broken. The only real downside with this solid build is it does have a tendency to make the Titan Attachments fairly heavy.

Built to Last

Of course, that is not too terribly likely to be a problem as one of the major focuses Titan Attachments placed on this tiller was its longevity – not always a point of focus for tillers.

- Is a 60” tiller

- Has a heavy-duty gearbox

- Has 28 oz tines

- Has 5 height settings

- Has reasonable power requirements

- Is a durable tiller

- Is a heavier tiller

3. Farmer Helper – Best Rotary Tiller for a Small Tractor

Compact Profile

One thing to consider when you have a smaller tractor is how many passes you will have to make and how compacted the soil will be. However, the Farmer Helper still provides a solid 48” working width. When you have a smaller tractor, you will inherently be more limited with respect to your implement options if for no other reason than because your tractor’s engine will begin to struggle. Thankfully, Farmer Helper understands that not everyone has a large tractor and ensured that their till could be operated with as little as 18 hp and not have to worry about a drop in digging power.

Digging Power

Though this tiller may have the fewest tines spaced on numerous flanges, their 1 ⅓ lb heft still provides plenty of digging power.

- Is a 48” tiller

- Has reasonable power requirements

- The lightest tiller reviewed

- Has powerful tines

- Has a durable drive

- Is a chain-driven tiller

- Has the shortest maximum digging height

Best PTO Tiller – Buyer’s Guide

Width

For many tractor-pulled and driven implements, the working width is one of the most important factors to consider. From a fairly basic standpoint, the working width is important because the larger the working width, the more area is covered in a single pass. The fewer passes you have to make over the property with the implement, the quicker you can complete your job. However, the working width does carry with it some important factors to consider if you are looking to expand. While most tillers hover between four and five feet in width, some will go up to six or even seven feet. Granted, there are technically larger implements out there, but then you begin to get into industrial farming and landscaping.

Specifically, the larger the working width of your tiller, the more expensive the tiller is going to be at every step of the process. Of course this includes the initial point of purchase, but the ‘costs’ of a larger tiller will continue through the use. This is because larger tillers are heavier than smaller ones but so much so that they often require a stronger tractor to pull them. On top of that, the wider the tiller generally the more tines and flanges which all require power from the tractor’s motor to dig further increasing the minimum tractor level necessary to run it.

Digging Height

Depending on your regions, the state and type of soil, and the reason for tilling, the digging height may be one of the more important considerations or little more than an afterthought. Basically, if you live in a region that has naturally excellent soil and you use the various rotation and growing techniques to help keep it that way, digging height is not too terribly important so long as you dig deep enough. However, if you are working with grounds that are far less forgiving, the digging height might be a necessary function which allows you to even effectively complete your task.

Basically, different types of dirt will require a different tilling technique. For instance, compare a rich dark soil to a thick red clay. The clay likely has plenty of rich nutrients but is not in a state ideal for growing and will be incredibly difficult and taxing to till in the best of situations. In this case, you might actually make multiple passes over the ground, digging a little bit deeper each time, to make the tilling easier without jamming your tiller’s gearbox or over-taxing the drive.

Tools

For instance, if you have a large number of tines on many flanges, you will be able to quickly and effectively till loose soil but will run into much bigger problems with rocky soil. Conversely, an arrangement with fewer tines on fewer flanges allows the tiller to bounce off of rocky terrain without jamming of damaging itself but will struggle to dig into thick soil. As such it is a good idea to consider what type of soil you will be tilling and the arrangement of the tines more than the total number.

Weight

Much like we mentioned in regards to the width of the tiller, the weight will have a fair number of important implications regarding the optimal use. However, while the width will increase the weight of the tiller, there are a number of aspects that will increase the weight further without increasing the width. For instance, the most durable tillers are generally made of the thickest steel and will include the heaviest, most durable gearboxes and other drive components. None of these things will increase the working the width of the tiller, but they all increase the overall weight.

Of course, you need the tiller to be a little bit heavy, so the tiller’s own weight drives it into the soil to assist the digging action. However, the heavier the tiller is the more powerful the tractor that pulls it will need to be as well. On top of that, those components which can significantly increase the weight will also often require more power to be driven. Finally, the weight of the tiller can actually cause compacting if it is not well-designed, though this is not really much of an issue for major implement manufacturers.

Power

The other way that you can look at the power of a tiller is how much power it takes to run the tiller from a standard 540 rpm PTO drive shaft. This rating is given in maximums and minimums, with the minimum denoting the type of tractor that you will need to run the tiller. This is important because tillers that can handle more HP also generally require more minimum HP to run in the first place. This means that that powerful tiller that likely cost twice as much as its competitors will require a similarly powerful, and expensive, tractor to properly run it.

Conclusion

While not always true, the adage ‘you get what you pay for’ definitely applies to the rotary tiller market, though it is at least not an all or nothing wasteland otherwise. Still, the King Kutter’s 72” working width combined with a durable build both inside and out is tough to compete with – from a performance perspective. If you are looking for something a little less expensive, the Titan Attachments offers a solid option with a 60” working width and the widest range of digging heights. Finally, those with smaller tractors would probably do better with the Farmer Helper’s compact profile to prevent compacting the soil.

Leave a Reply